About Us

Shanghai Dunhe Technology Development Co., Ltd.

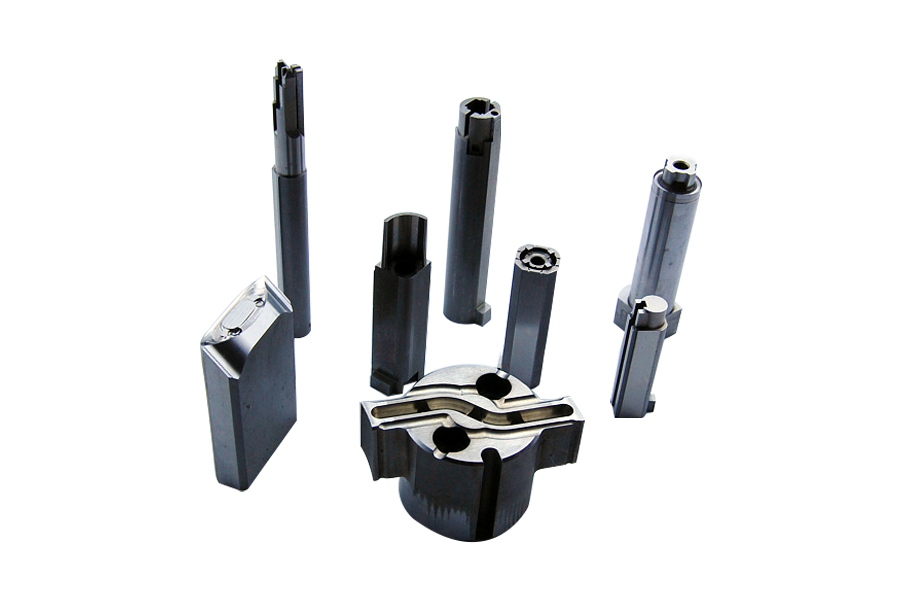

Shanghai Dunhe Mold & Plastic Technology Co., Ltd. was established in 2018. It is a one-stop manufacturer specializing in the design and manufacture of precision injection plastic molds, the production and assembly of precision plastic parts, and is committed to auto parts products, automotive wiring harness connectors, home appliances. Design and manufacture of molds for peripheral products such as electrical plastic parts, electronic plastic parts, ampoule disposable packaging materials, and cosmetic packaging materials. The company has imported advanced mold processing equipment and injection molding equipment from Japan, and has a professional engineering and technical personnel team. Effective management ensures mold quality and professional services. Now our customers are mainly located in China, South Korea, Japan, Vietnam, Philippines, Indonesia, and France and other countries.

Founded

Employee

Equipment investment

Sales

Honor

Products

Focus on the design, manufacture and sales of injection molds; the manufacture and sales of mold cores and cores

Technical Strength

The company follows the concept of "customer first and attentive service" to meet the needs of customers as its service purpose

News Center

Understand company information, pay attention to industry trends in real time, we will provide you with accurate and reliable information