china Cosmetics Equipment Parts

Category:

Cosmetics & Medical machinery parts

Hotline:

Details

Components of the ampoule kit - bottle body and base

china Cosmetics Equipment Parts

China Cosmetics Equipment Parts have a significant presence in the global cosmetics supply chain. Chinese manufacturers produce a wide variety of high-quality cosmetic equipment parts that are in demand worldwide. They offer cost-effective solutions without compromising on quality. These parts are used in the production of various cosmetic products, from skincare to makeup. Chinese manufacturers focus on meeting international standards and providing innovative designs to meet the evolving needs of the cosmetics industry. Their ability to mass-produce and customize parts makes them a valuable partner for cosmetic brands looking for reliable and efficient components. The reputation of China Cosmetics Equipment Parts is growing, and they continue to contribute to the growth and success of the global cosmetics market.

Prev

Cosmetics Equipment Parts manufacturers

Products

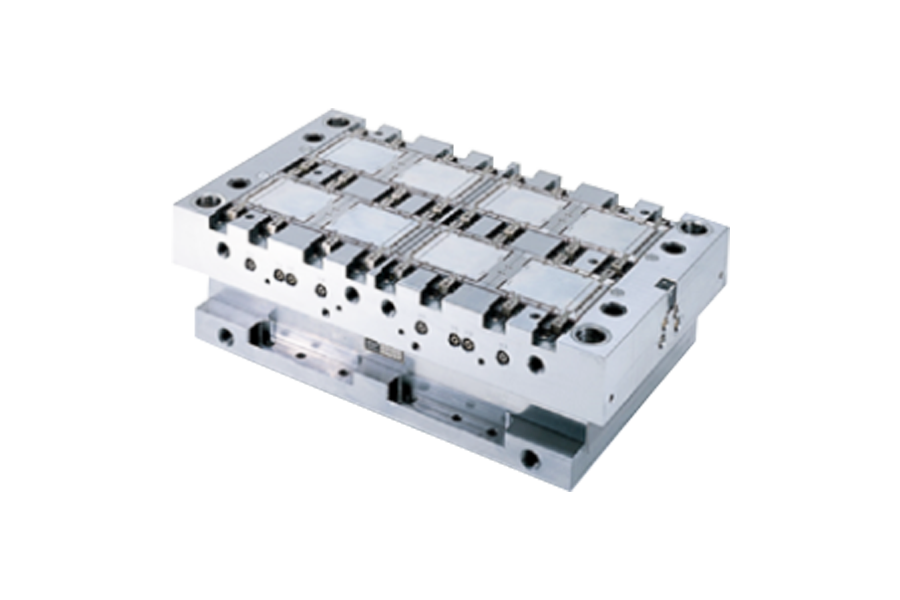

Yazaki-Connector Mold china

Connector Mold is a crucial element in the manufacturing industry. These molds are designed with precision and high-quality materials to ensure the production of connectors with excellent specifications. The molds might have features such as exact dimensions,

Yazaki-Connector Mold components

Yazaki-Connector Mold components are highly specialized and essential elements in various industries. Yazaki is known for its high-quality and precision-engineered connector molds and their components. In the automotive industry, these components play a critical role.

Yazaki-Connector Mold factory

A Yazaki-Connector Mold factory is a hub of precision and innovation. In such a factory, you can expect state-of-the-art manufacturing processes and high-quality output. The products might have specifications like tight tolerances, excellent material quality,

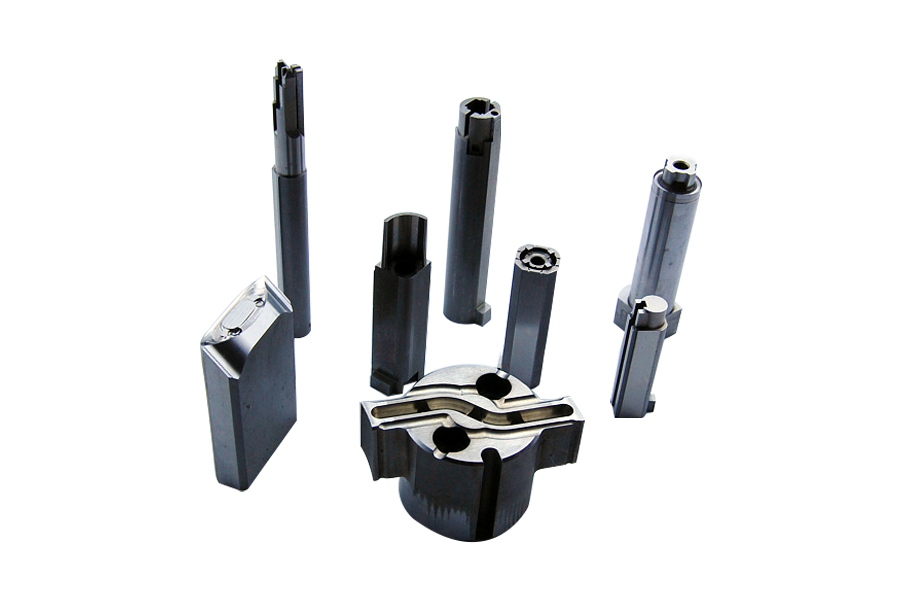

Precision Core precision mold

Precision Core precision mold is a remarkable innovation in the world of manufacturing. These molds are characterized by their extraordinary precision and quality. In the automotive industry, they are essential for creating complex components with exacting tolerances. Imagine a mold that can shape intricate parts for engines or transmissions, ensuring perfect fit and functionality. The unique selling point of these molds is their ability to achieve micron-level accuracy.

Messages